[Draft 6-30-2025, patched in some sketches for new scenes. On 7-20-2025 added links for NASA’s documentary “Cosmic Dawn.” On 8-4-2025 added Epilogue. On 8-5-2025 added a short scene.]

Deep Space Drift

An anthology

Fictional stories

Inspired by real-life events

Copyright © 2025 John P. Healy

Table of Contents

- Epigraph

- Prologue

- Tales of single point moments

- VENT BEFORE OPENING

- SCREWED BARELY?

- Notes

Epigraph

Over time … more with more … became more with less … and then just making do.

Prologue

Initial deployments of the Webb Space Telescope were among the most critical, and the riskiest. 344 single-point failures were identified in the spacecraft, 80% of which were associated with deployment (release) mechanisms.5

Yet, risk mitigation aside, vast networks of coordinated effort and relationships pose similar points of failure as well. And success may depend on moments where one person’s action or one decision is such a point.

There’s a saying:

- “When you do things right, people won’t be sure you’ve done anything at all” (Futurama S3 E20 3-17-2002).

- When a system or process functions flawlessly, it doesn’t draw attention to itself. It just works.

- When things go right, people might not realize the amount of work, planning, or problem-solving that went into making it happen.

Tales of single point moments

VENT BEFORE OPENING

• Mindful of margins

High over Paris there was a crunch. Brian’s sleeping brain wove that sound into his dream, a scene of doom, as another note in the stress & excitement of his mission.

That note jolted him awake. Across the aisle a young boy had crushed a soda can. The kid looked pleased with his show of strength. Perhaps he’d seen social vids of young men crushing beer cans against their foreheads.

But for Brian it was a reminder of the pressurized cabin in which he flew, the consequences of changes in air pressure1, the margins of safety.

Soon after, the “fasten seat belt” sign came on. He returned his seat to an upright posiiton and put away his computer; then readied himself for air turbulence as the plane started its descent. Some bumpiness.

There was a carefully boxed item in the plane’s cargo. It contained a spare part for something going into space.

Brian used the time during descent and the delays before deplaning to recollect the swirl of recent events.

• No pearl inside

•• The review meeting

The meeting had started okay, but Eric felt increasingly irritated. The discomfort in his gut came on whenever he sat in on one of John’s department meetings. Perhaps like a clam when a small particle is introduced inside its shell. But no pearl would result from this stress.

Both of them had graduated from MIT. While their management styles differed, it was John’s incessant, repeated use of the phrase “if you will” that drove Eric crazy.

The agenda for the department meeting was posted earlier in the week. So, Eric didn’t expect anything unusual. His department followed regular order as well. He recognized the section heads seated around the large conference table. Today, as an observer, he sat near the wall in the back, near the door. His lead systems engineer Brian sat next to him.

Basically everyone was there to once again cover a checklist of revisions to the launch vehicle fairing. Brian was agitated as well, and whispered, “Eric, can you believe how John bullies his team?”

“Yeah, that seems so old school, like he really doesn’t want anyone rocking the boat with new questions,” Eric replied.

Brian nodded, then remarked, “I’ve been looking at some new data.”

“Okay, let’s talk at lunch.” After a few more “if you will” moments, they both quietly left the room.

•• The lunch chat

“So, Brian, tell me more about this new data.”

Brian said, “Sure.” After looking around the cafeteria, he continued, “Eric, you might say that it deals with assumptions. The improved acoustic protection on the fairing’s interior makes sense. But the vents … well, the data shows that they probably partially close. The Webb’s sunshield stack is something new, quite fragile. Like a tightly packed, layered sandwich. Remember that tear during recent tests? So, I’ve been thinking more about pressure differentials, possible air pockets inside the stack if all the vents don’t stay open before the fairing opens.”

“I see. Anyone else looking at this?”

“Not that I’m aware of. Knowing how to run sim’s is one thing, but there’s the time, and everyone’s already stressed out,” Brian explained.

“Sounds like this might be appropriate to raise at the next ‘all hands’ meeting. If there’s an opportunity.”

• One raised hand (‘all hands’ holdout)

This was a larger powwow. A larger conference room. More staff members in rows of chairs around the walls. More projected visuals, as each technical department head presented. Bill (‘no drama’ Gama), the lab chief, stuck to regular order. Until … just before lunch …

Bill said, “I appreciate all of you going over things yet again. Sounds like subcontractors have been responsive to all your queries. Particularly the fairing contractor. We need to be sure there’re no loose ends. There’s a limited window of opportunity to tweak the design. That opportunity is provided by other customers using the same launcher for their upcoming missions. So, I’d like a show of hands. Raise you hand if you feel there’s something we’ve missed, something to look at further?”

Everyone there looked around. Some picked up their backpacks. Brian nudged Eric and cleared his throat. Eric reflexively raised his hand, and said, “Well …”

John had a smirk on his face, as if saying, “You really put your foot in it this time.” Eric’s was the only hand raised.

• Executive caution

Eric arrived a few minutes early at his boss’ office. His executive assistant quickly noted that Bill was running somewhat late and that Eric & Brian could go in anyway. Lunch had already been ordered and arranged.

Eric had been to Bill’s suite on a somewhat regular basis before, where they met in the small conference room. But this was something new – to actually be inside Bill’s private office. Impressive. Wood paneling. A window extended across most of one wall. There was an expansive desk with a multiscreen workstation. Built-in shelves with books and plenty of industry photos and company mementos and spacecraft models. Including, of course, Space Telescope models and posters. Lunch was arranged on a large countertop, near one end of the wall inside the door. Like a hospitality nook, with a round table & chairs.

But what drew Brian’s attention immediately was not the food but some posters on the wall above. Music posters, in particular celebrations of famous guitar players and their axes. Then he noticed a guitar propped behind Bill’s desk.

Brian called out to Eric and pointed, “Hey, look at that! I wonder if that’s his favorite!” He walked forward to get a closer look.

Eric paused from sipping a can of soda and replied, “Ah, yes, you’ve quite a bunch of guitars yourself. Maybe, like you, he was in a band in school and still plays.”

Eric felt somewhat relieved with the situation. He wasn’t sure what to think after the last lab powwow. Bill had waited until everyone else had left; then said, “Let’s talk, my assistant will let you know when.” Maybe this wasn’t about being sanctioned.

Both of them set down their backpacks near a chair, then selected a sandwich & side (just one for now, eh) and gourmet cookie from the buffet. Brian eyed the hot drinks, but settled on a Perrier. Eric started on another soda. They settled at the round table. From his backpack, Brian took out his notebook computer and a few cases; then a copy of Guitar World.

Bill walked in, glanced at the table, smiled, then greeted them, “Gentlemen, glad to see you getting started. I’ll join you in a minute.”

He walked over to his desk, unloaded some papers, and checked his screens. His expression was contented. He touched his guitar’s strings as he returned to join Eric & Brian, getting some coffee and a sandwich.

Bill loosened his tie, “Okay, looks like Brian and I share a musical passion. I’d like to chat about that, but first here’s some context. I’m here to listen, explore systems questions together, nurture the bandwidth to do the impossible10. Checking subcontractor workflow took longer than expected earlier. … Looks like you’re ready to demonstrate something.

“But, Brian, let’s talk about guitars …”

Eric listened while Bill & Brian chatted about their music and favorite playlists. He didn’t play any instruments, but understood the passion. A nephew had been a touring musician for several years, before other band members started settling down, and had wound up in the Internet of things. Making do.

But today reminded Eric of a summer job in college. He worked at a defence contractor’s shop as an engineering trainee. Drafting table and all. He was tasked to analyze … a large mechanical system enclosed in pressurized water. A long metal rod needed to shut down in an emergency. He’d struggled with the lack of information on the system. Just some basic design specs, a few internal temperature readings. He needed to build a model, make some assumptions, do the math. He hadn’t been confident about the results. There was no one else in the shop to consult. But the team managers were satisfied, even saying that he’d finished the job quicker than expected. He always wondered if his work became the basis for some critical decision.

A guitar riff brought Eric back to the current meeting. Brian was smiling, holding Bill’s axe.

Bill said, “Okay, let’s talk risk management. Enjoy more food & drink as we chat.”

Eric took the cue, “Thanks … You know I like to wander around, chat with other teams outside formal channels, regardless of job titles. My systems engineering responsibilities provide some cover, some plausibility for bothering them, but sometimes it’s politically risky10. You’ve been supportive. Even so, I’m reluctant to second guess other teams conclusions, particularly subcontractors. I don’t want to be the guy who does a line stop on a production process, especially one with a seasoned track record.”

Brian looked up from his notebook and nodded.

“But assumptions are tricky things. Part of the general challenge of incomplete information. It’s my job to note assumptions in requirements specifications. Certainty10 – where assumptions are hidden – can impact margins of safety.

Bill said, “I agree. Please go on.”

“Our recent family & friends open house in the high bay reminded me … So much excitement … the kids had so many questions, especially about the huge vacuum chamber. Shake & bake. Several engineers had set up interactive school science kits which demonstrated what happens to things in a vacuum. Like bubble wrap, tiny marshmallows, shaving cream.”

Brian looked up again and remarked “Yes, that was fun.”

“Close by was the display about the sunshield. One of the design engineers was handing out origami sculptures, showcasing how you can take complicated 3D objects and flatten them9. Amazing artistry.

While lunch & treats were served for our visitors, I found myself thinking about a huge finely layered s’more cookie bar being deployed into space.

Brian smiled and said, “Yeah, we all were hungry by then.”

Eric chuckled, “Anyway, that’s when I asked Brian about what simulations had been done for fairing separation, for prior launch vehicle missions and ours. … So, Brian, ready?”

Brian had removed a few items from cases. He replied, “Yes, this sim is sort of rough, yet to be run on our main supercomputer; but the drift is there – that safety margins might be squeezed during depressurization. I can show you a few charts on my screen unless you’d prefer to use your projector.”

Bill replied, “That’s fine, go ahead.”

Brian continued, “So, I modeled the payload area and spacecraft using current specifications. I used higher detail for the sunshield stack. Using what info we had on the fairing’s pressure vents and the timeline for venting and separation, I ran several scenarios for likely profiles of depressurization rates and residuals. It’s basically a fluid dynamics model, analyzing turbulent and laminar flows. The twist was including the layered passages and effective surface properties of the stack. That produced stalled scattered eddies – air pockets, if the vents don’t stay open long enough. We need to test a vent.”

[Additional discussion]

Pointing to the items near his notebook, Brian said, “There’s one last thing. In homage to Richard Feynman and his glass of cold water and piece of rubber8, I have some brief videos of this science kit – showing what happens to things containing trapped air bubbles in a vacuum.”

[To be continued]

• Contractor rebuff (fairing contractor)

• A good day to garden (cold call)

• The pitch

• Reducing risk

[Section: “We’ll always have Paris”]

[Scene: No one wants to be a worrywart, but …]

From his hotel window, Brian gazed out at Paris, pondering the upcoming meetings at the ESA. This was a big deal. Company briefings back home had helped set the stage for the discussions, the many stakeholders, both directly and implicitly. His role was technical, to clearly lay out the results of his team’s analysis of the fairing vents, and the concern about the impact of residual air pressure on spacecraft soft structures on opening the fairing – “billowing.”

Brian didn’t want to be seen as a worrywart. And being a squeaky wheel was out of place as well. Some kind of balance. He’d been counseled to let the discussions follow the data. Especially since there likely was data that his team was not aware of. And hopefully get beyond any stovepiping.

The programmatics would follow. For that really was the bigger picture, to realize a path forward, a plan which all stakeholders could feel comfortable with. A buy-in, from which responsibilities, schedules, and costs can be determined.

For risk management didn’t come free. When was enough enough? Reputations required respect. Yet, without full understanding of air pressure residuals, the series of successful past launches was no guarantee that there was no issue for the JWST. The stakes were astronomical, both for budgets and reputations. No one wanted to be seen in hindsight as a scapegoat.

He picked up his phone and checked for messages.

[Scene: Sweating the data]

From the roof of the ESA building, Brian gazed out at the Parisian skyline. The many flags of participating ESA members fluttered in the wind nearby. The weather was warm, the building lacked AC. He’d needed some air and enjoyed the view.

There’d been a lot of introductions initially. And just figuring out the roles of the various ad hoc subcommittees and how that played into the larger review of findings.

And, of course, there was the language thing, not just the many voices. Brian had to be patient at times with translations or levels of fluency. But he was amazed, as in college, that international partners generally spoke English so well, while his team spoke hardly any of their language.

Some of the participants were quite vocal. Many others quiet. Those more vocal sometimes came across as heavy-handed, with strong statements, without nuance. Mild posturing. Maybe some of that was a way to elicit participation from the more reserved.

And that impression sometimes played out in the cafeteria. Or during breaks for refreshments. (Ah, those refreshments …) Before the trip, Eric had shared an old anecdote, a classic tale, about a manager taking away all the coffee / refreshment nooks in the workplace in order to improve efficiency – claiming that too many engineers were “wasting” time there. Well … how’d that work out, eh.

He chuckled to himself, “And, how do you eat a whale? – one bite at a time.”

Brian enjoyed the breeze for another moment. He finished his soda, the can free of any dents; then took a photo of the view, and returned inside.

…

• The long wait

[Scene: Emoji meld]

Brian and some of his team members stood in the operations room at the Space Telescope Science Institute, staring at some displays. It was a familiar place to be, another 2-week stay in Baltimore.

But it was THE day at last. For them and many others around the world. They monitored data streams, as the Ariane 5 lifted off and deployed the Space Telescope. All went well. There was relief & euphoria.

On one of the displays, Brian sent happy emoji messages to other team members back in Los Angeles. But the LA messages presented a contrast for the moment. They contained sad emojis. Sadness for not being there, for not being together for the celebration.

The last few days reminded him (once again) of the exceptional journey that he (and so many others) had been on for years (and some even for decades). A shared resolve which had to come from within. A commitment which could not be commanded. Not by a request to “suck it up.” But by a personal desire to make it happen, by a shared sacrifice among teams and families.

Awhile ago, Brian had felt a different vibe from comments by parents of one of his kid’s friends. About his workload – all the long hours, the time away from home, the variable schedules. Like was it all worth it? – doing more than enough, more than necessary.

Yet, that was the shared passion – a meld of so many teams, for one shot to boldly do something impossibly new.

Program veterans didn’t see their work environment as a “grind culture.” But there was a saying – about dealing with the enduring intensity: “chunk, hunk, or drunk.” Brian had dealt with the first two by portion sizing and weight training at a local gym. The third wasn’t a go-to anyway.

The COVID pandemic had jiggered program schedules and slowed progress on already recognized problems. The Webb Space Telescope was not prioritized in the same category as immediate health, safety, and operational needs. Early on, some work was suspended. And remote work could only do so much. “Don’t push the river.” So, there were times when late in the day his peers just called out, “It’s time to go home.”

And soon there might be more days like that back in LA. For a while at least … in a landscape of changing federal funding.

[End scene: The last man to touch the JWST]

Years later, one evening at A Rocket High, relaxing during a break after playing the song “Space Oddity,” Brian made a toast. He recounted an anecdote about the day that the Ariane 5 rocket stood ready to launch the Space Telescope. A day long awaited.

“Imagine that scene at the launch site … the last man to touch the JWST. A garbed & gloved technician crawling out on a “diving board” to reach a small access door in the fairing … for one last procedure … final closeout. With a last look-see, he closes the purge interface for the cleanroom air inside. ‘Out with the bad air … !’

“Let’s raise our glasses. That must have been a moment! Here’s to all those moments which made the mission a success!”

As Brian put down his glass, watching the bubbles rising inside, he was mindful that the gas inside the fairing relied on vents, vents that released the air during flight and before the fairing opened.

Epilogue

so that a higher vision survives

star sight, star shining so bright

gazing into cosmic light

such a fragile work of man

an unfolded origami

a curious golden eye

answering the call of why

we seek ever farther sight

to obtain better insight,

connect more dots in our past,

beacons to guide us forward

•

so many came together to mount

this impossible long-shot journey

to grow bounds of imagination

and augment lore of human passion

at a million miles away in space

by a halo loop it stays in place,

so many wondrous views revealing,

even of our cosmos emerging

whether we can ever encompass

such vast scales manifest before us,

we yet stand looking to nightly sky,

telling new tales in starry figures

•

perhaps a prelude to map a path

someday to other worlds, other suns,

so that what we carry with us there

is deeper than the surface of things

may voices still to come sing human hope

that we sought more than ascendancy

or heavenly place as but haven

for refugees from conflicted lands

we remain ever pilgrims of purpose

drifting in ever expanding flight

aspiring there for something better,

a higher peak of eternal light

•

stardust though we be,

the risk was taken,

the resolve was kept,

a singular chance

with all so many

single point moments

[11]

Afterword

17 December 2021

More technical references

Additional technical information

2025 film “Cosmic Dawn”

Mike Menzel, Webb Mission Systems Engineer:

If you’re going to have 344 single point failures; and they’re all dependent on the last reset, on the last installation, you have to have an environment of absolute openness and honesty.

And the fear that comes from the politics and that kind of stuff is your chief enemy to that.

On June 11, 2025, NASA (Goddard Digital Team) announced the release of a film which celebrates “the extraordinary people who made it all happen, for the benefit of humanity.”

Cosmic Dawn is now available for streaming on NASA’s YouTube, NASA+, and select local theaters. The trailer is available on NASA+ and YouTube.

• Space.com > “Go inside the development of NASA’s $10 billion James Webb Space Telescope with new ‘Cosmic Dawn’ documentary” by Kenna Hughes-Castleberry (June 15, 2025)– “There was nothing easy about Webb at all.”

For space fans, June has something extra to enjoy, as NASA recently released “Cosmic Dawn,” a new “intimate access” documentary all about designing and assembling the James Webb Space Telescope.

The story of the James Webb Space Telescope begins 30 years ago, as NASA scientists were beginning to discuss a new space telescope, then called the Next Generation Space Telescope. Over the next three decades, NASA collaborated with the European Space Agency and the Canadian Space Agency to design a telescope of incredible ambition and complexity. The project ended up costing over $10 billion — far above the original estimate —and involved thousands of scientists, engineers, and technicians worldwide.

Woven throughout the documentary are several personal stories from the engineers and scientists working on the project.

• NASA+ > Cosmic Dawn: The Untold Story of the James Webb Space Telescope (June 11, 2025) [~96′]

SCREWED BARELY?

- One raised hand (is ball in or out?)

- “Analyze this!”

- Line call

- Mending manners (moving on)

- The long wait

Notes

[1] A common demonstration in science class.

• Wiki > Collapsing can

Note AI’s response to Google search for “high school science demo the power of vacuum to crush a can.”

[2] Getting a space telescope into space is only part of the drama.

Basically the issue was loading on the spacecraft due to any “pressure differential once the fairing is separated.” That is, failing to adequately equalize pressure inside & outside before exposure to space (vacuum).

• Wiki > James Webb Space Telescope

• Wiki > Ariane 5

The VA253 launch on 15 August 2020 introduced two small changes that increased lift capacity by about 85 kg (187 lb); these were a lighter avionics and guidance-equipment bay, and modified pressure vents on the payload fairing, which were required for the subsequent launch of the James Webb Space Telescope. It also debuted a location system using Galileo navigation satellites.

On 25 December 2021, VA256 launched the James Webb Space Telescope towards a Sun–Earth L2 halo orbit. The precision of trajectory following launch led to fuel savings credited with potentially doubling the lifetime of the telescope by leaving more hydrazine propellant on board for station-keeping than was expected. According to Rudiger Albat, the program manager for Ariane 5, efforts had been made to select components for this flight that had performed especially well during pre-flight testing, including “one of the best Vulcain engines that we’ve ever built.”

Google search:

“Ariane 5 modified pressure vents on the payload fairing”

Example result:

• Ariane Group > “Everything You Always Wanted To Know About The Launch Of The James Webb Space Telescope But Were Afraid To Ask” (12-21-2021) – Interview with Stéphane Leboucher, Head of Ariane Mission Preparation and Customization

‘@ArianeGroup – James Webb Télescope Spatial

Is there anything different about the launcher this time?

Yes, the vents on the fairing in particular have been modified to prevent the risk of depressurization that could damage Webb when the fairing is jettisoned. This could have happened if residual air were to be trapped in the folded membranes of the James Webb sunshield. The modifications were successfully tested on the last two Ariane 5 flights on 30 July and 23 October. Our fans will also be happy to know that this time, Ariane 5 is carrying a video system (nicknamed Viki), so that all stages of the launch can be closely followed.

• NASA Spaceflight > Forum > Ariane 5 fairing separation – includes photos of a fairing vent and vents around the lower section in the interior of a fairing half, with remarks that “JWST is too precious to risk” (a one-off) and about the Ariane 5’s operational life, specs, and cost.

• Jan 27, 2021 JWST update by Eric P. Smith (PDF)

• ESA > “Ariane 5’s third launch of 2020” (8-16-2020)

A further modification to Ariane 5’s fairing will minimise depressurisation at separation as this two-part nose cone is jettisoned away from the launch vehicle in space. Manufactured by RUAG Space Switzerland, the fairing protects the customer payloads from the acoustic, thermal and aerodynamic stresses during the ascent. New hardware ensures that venting ports around the base of the fairing remain fully open on the way to space, allowing the pressure to equalise within the fairing prior to opening and falling away from the rocket.

This alteration is part of the preparation for the launch of the NASA/ESA/CSA James Webb Space Telescope (JWST) set for October 2021. These changes mitigate concerns that residual air pressure in the folds of the JWST sunshield membranes could cause high stresses at the time of fairing separation, potentially damaging sensitive components.

[3] JWST Sunshield protection

• Wiki > James Webb SpaceTelescope > Sunshield protection

The sunshield consists of five layers, each approximately as thin as a human hair. Each layer is made of Kapton E film, coated with aluminum on both sides. The two outermost layers have an additional coating of doped silicon on the Sun-facing sides, to better reflect the Sun’s heat back into space. Accidental tears of the delicate film structure during deployment testing in 2018 led to further delays to the telescope deployment.

The sunshield was designed to be folded twelve times so that it would fit within the Ariane 5 rocket’s payload fairing, which is 4.57 m (15.0 ft) in diameter, and 16.19 m (53.1 ft) long. The shield’s fully deployed dimensions were planned as 14.162 m × 21.197 m (46.46 ft × 69.54 ft).

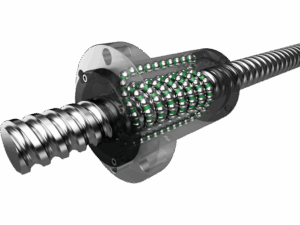

[4] JWST sunshield deployment – deployment tower assembly (DTA) – ball screw assembly bearings (friction margins for extended operation)

• Wiki > Ball screw

• Google search: “jwst sunshield mechanism screw drive”

AI Overview

The James Webb Space Telescope (JWST) sunshield deployment involved a complex mechanical system, including screw drives as part of its deployment tower assembly (DTA). This mechanism played a crucial role in the initial deployment and tensioning of the sunshield layers.

Here’s how the screw drive mechanism is used:

Deployment Tower Assembly (DTA): The DTA consists of inner and outer tubes that translate relative to each other.

Ball Screw: A 6-foot ball screw is mounted within the DTA, acting as the primary driver for translating the tubes.

Stepper Motor: A gear motor, specifically a 3-phase, 4-pole, permanent-magnet stepper motor, drives the ball screw.

Planetary Gearbox: The motor is connected to a 576:1 planetary gearbox, which increases the motor’s torque to provide sufficient power for driving the ball screw.

Actuation Sequence: The stepper motor rotates the ball screw, causing the ball screw nut to translate along the screw. This translation of the nut then either pulls a flexure to achieve the stowed preload or pushes it to achieve the deployed preload.

Deployment Steps related to the screw drive:

Stow Preload: The stepper motor rotates clockwise to achieve the desired preload in the stowed position, reaching a flexure load of at least 1750 lbs.

Motor Off: The motor power is turned off once the flexure strain limit is reached in the stow preload.

Unload and Deploy: The stepper motor rotates counter-clockwise to unload the flexure and extend the ball screw, enabling the sunshield deployment.

Deployed Preload: The ball screw continues to advance past the end-of-travel stop to preload the flexure to a minimum of 1350 lbs, ensuring the sunshield is properly tensioned.

In essence, the screw drive mechanism, driven by a stepper motor and planetary gearbox, is vital for the initial deployment and tensioning of the JWST sunshield by precisely translating the DTA tubes and applying the required preload to the flexure.

AI responses may include mistakes.

[5] Deployment involved a series of first-of-its-kind complex deployments and maneuvers once the spacecraft separated from the upper stage.

• Space News > “JWST launch marks only the start of a risky deployment process” by Jeff Foust (December 23, 2021) – The liftoff marks only the beginning of the riskiest part of the mission.

• Northrop Grumman > “One Shot to do the Impossible” by Adam Stone – The Intense Testing of the James Webb Space Telescope

[6] Regular order entails doing things in an agreed upon way. This agreement may be based upon tradition. Or on institutional culture, as in “the NASA way.” Our modern political culture has the same mindset (at least until quite recently).

• CBS News > Face The Nation > “John’s Notebook: What is ‘regular order’?” by John Dickerson (September 24, 2017)

Regular order is Washington jargon, but it basically means doing things the agreed upon way.

In Congress, regular order is the process for tackling tough problems – studying them, applying expertise and arguing them on the merits without personal attacks.

It’s also a mindset for a place where everyone has to work together the next day. It sets the conditions for heated arguments so everyone feels heard and respected. It grounds debates in the values of the institution – fairness, equality, justice – which temper the passions of the moment.

Regular order doesn’t always lead to compromise. But compromise is less likely without it. Regular order doesn’t always mean less partisanship. Partisan hotheads can still hijack the public process.

But without regular order people get suspicious of the final product. Losers feel cheated and invited to undermine the law.

[7] Systems engineering is another agreed upon way to tackle the development of complex systems. Across the complete life cycle of those systems. It uses an interdisciplinary framework to choreograph a shared vision across all stakeholders, technical disciplines, engineering teams, manufacturers, and end users.

• Wiki > Systems engineering

Systems engineering is an interdisciplinary field of engineering and engineering management that focuses on how to design, integrate, and manage complex systems over their life cycles.

The systems engineering process is a discovery process that is quite unlike a manufacturing process. A manufacturing process is focused on repetitive activities that achieve high-quality outputs with minimum cost and time. The systems engineering process must begin by discovering the real problems that need to be resolved and identifying the most probable or highest-impact failures that can occur. Systems engineering involves finding solutions to these problems.

Systems engineering encourages the use of modeling and simulation to validate assumptions or theories on systems and the interactions within them.

[8] The Space Shuttle Challenger disaster remains a case study in transparency and accountability within NASA.

• Wiki > Space Shuttle Challenger disaster (January 28, 1986)

The cause of the disaster was the failure of the primary and secondary O-ring seals in a joint in the right Space Shuttle Solid Rocket Booster (SRB). The record-low temperatures on the morning of the launch had stiffened the rubber O-rings, reducing their ability to seal the joints. Shortly after liftoff, the seals were breached, and hot pressurized gas from within the SRB leaked through the joint and burned through the aft attachment strut connecting it to the external propellant tank (ET), then into the tank itself.

The disaster resulted in a 32-month hiatus in the Space Shuttle program. President Ronald Reagan created the Rogers Commission to investigate the accident. The commission criticized NASA’s organizational culture and decision-making processes that had contributed to the accident. Test data since 1977 had demonstrated a potentially catastrophic flaw in the SRBs’ O-rings, but neither NASA nor SRB manufacturer Morton Thiokol had addressed this known defect. NASA managers also disregarded engineers’ warnings about the dangers of launching in low temperatures and did not report these technical concerns to their superiors.

During a televised hearing on February 11, Feynman [Richard Feynman] demonstrated the loss of rubber’s elasticity in cold temperatures using a glass of cold water and a piece of rubber, for which he received media attention. Feynman, a Nobel Prize-winning physicist, advocated for harsher criticism towards NASA in the report and repeatedly disagreed with Rogers. He threatened to remove his name from the report unless it included his personal observations on reliability, which appeared as Appendix F. In the appendix, he lauded the engineering and software accomplishments in the program’s development, but he argued that multiple components, including the avionics and SSMEs in addition to the SRBs, were more dangerous and accident-prone than original NASA estimates had indicated.

See also:

• Wiki > Rogers Commission Report (1986)

• Book > What Do You Care What Other People Think? by Richard Feynman (1988) – Appendix F, Epilogue > The Value of Science

• Wiki Quote > Richard Feynman

Let us make recommendations to ensure that NASA officials deal in a world of reality in understanding technological weaknesses and imperfections well enough to be actively trying to eliminate them. They must live in reality in comparing the costs and utility of the Shuttle to other methods of entering space. And they must be realistic in making contracts, in estimating costs, and the difficulty of the projects. Only realistic flight schedules should be proposed, schedules that have a reasonable chance of being met. If in this way the government would not support them, then so be it. NASA owes it to the citizens from whom it asks support to be frank, honest, and informative, so that these citizens can make the wisest decisions for the use of their limited resources.

For a successful technology, reality must take precedence over public relations, for nature cannot be fooled.

[9] Origami-inspired spacecraft design, Webb as a piece of enormous origami …

• YouTube > How NASA Engineers Use Origami To Design Future Spacecraft (Mar 25, 2018) – at 3:49 / 4:20.

• NASA > “Webb and Origami” – see highbay photos (thermal vacuum testing chamber, sunshield structure, Ariane 5 rocket fairing, …) and Deployment video

• Caltech > Origami Sunshield Concepts for Space Telescopes by Lee Wilson∗ and Sergio Pellegrino† (California Institute of Technology Pasadena CA), Rolf Danner‡ (Northrop Grumman Aerospace Systems, Redondo Beach, CA)

[10] As noted in my May 20, 2019, comment on “Feynman’s legacy — quantum originality,” raising questions can be tricky, gauging receptivity. Feynman noted that “it’s a question of whether, when you do tell somebody about some problem, they’re delighted to hear about it … [or] you try once or twice to communicate and get pushed back, pretty soon you decide ‘To hell with it.’“

Reference: What Do You Care What Other People Think? Further Adventures of a Curious Character — Richard P. Feynman as told to Ralph Leighton © 1988

Part 2

MR. FEYNMAN GOES TO WASHINGTON: INVESTIGATING THE SPACE SHUTTLE CHALLENGER DISASTER [January 28, 1986]

Page 128

The main thing I learned at that meeting was how inefficient a public inquiry is: most of the time, other people are asking questions you already know the answer to — or are not interested in — and you get so fogged out that you’re hardly listening when important points are passed over.

Page 214 – 215 [re the “selling” of the shuttle]

Maybe they [management] don’t say explicitly “Don’t tell me,” but they discourage communication, which amounts to the same thing. It’s not a question of what has been written down, or who should tell what to whom; it’s a question of whether, when you do tell somebody about some problem, they’re delighted to hear about it and they say “Tell me more” and “Have you tried such-and-such?” or they say “Well, see what you can do about it” — which is a completely different atmosphere. If you try once or twice to communicate and get pushed back, pretty soon you decide “To hell with it.”

So that’s my theory: because of the exaggeration at the top being inconsistent with the reality at the bottom, communication got slowed up and ultimately jammed. That’s how it’s possible that the higher-ups didn’t know.

The other possibility is that the higher-ups did know, and they just said they didn’t know.

EPILOGUE: The Value of Science

Page 248 [re “the open channel“]

It is our responsibility to leave the people of the future a free hand. … [Otherwise] we will doom humanity for a long time to the chains of authority … It has been done so many times before.It is our responsibility as scientists, knowing the great progress which comes from a satisfactory philosophy of ignorance … to teach how doubt is not to be feared but welcomed and discussed; and to demand this freedom as our duty to all coming generations.

[11] As this more recent article discusses, NASA built itself “as a brand in the global imagination.” But now its inspirational credo (“an ambition at once humble and endless”) and international stature are adrift.

• Wired > “The Destruction of NASA Would Be a Blow to Our Collective Imagination” by Richard Warnica (8-21-2025) – For many NASA veterans and enthusiasts, budget cuts & workforce impacts seem like the end of the American desire to look outward, just to look.

What’s being undercut isn’t just NASA’s technical ability to carry out missions, although that would be bad enough. It is America’s – and the world’s – capacity to wonder, to believe, to know. “It’s almost like a diminution of our own vision and ambition to say we’re literally, I mean, again, not figuratively, literally, closing our eyes to the cosmos and turning inwards,” says Casey Dreier, the space policy chief at the nonprofit Planetary Society. “It’s like witnessing a death of an ideal.”

“We had built something, have built something, as a nation so unique in the course of history,” Dreier says. “It’s kind of astonishing, when you think about it, the level of not just ambition, but willingness to say, we’re going to go and figure out what the universe looked like within years of its existence. … And why? Not for domination, not for glory, but for this joint collective desire to know our cosmos better.“